Leading the way with EcoLite™

full composite construction

What is full composite construction?

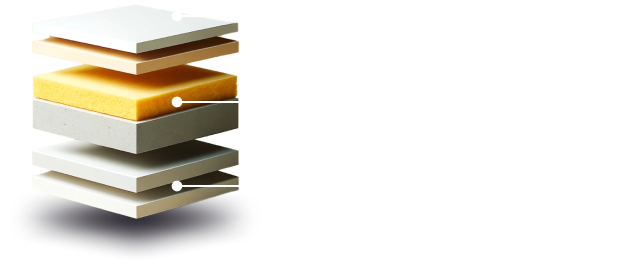

Full composite construction is an advanced method of frameless caravan construction. The process entails bonding 3 layers of different materials together to form structural panels for the floor, walls and roof. This material is sometimes referred to as a sandwich panel due to its two outer layers and one inner layer, just like a sandwich. Various forms of composite-based materials are commonly used in the construction of trucks, trains, trams, planes and boats. This is because composite materials have a high strength-to-weight ratio. This means it’s lightweight yet also strong.

Crusader Caravans is leading the way in the Australian caravan industry with its innovative use of composite materials called EcoLite. This unique combination of advanced manufacturing methods and custom engineered materials used by Crusader Caravans delivers superior caravan roof, floor and wall panels. EcoLite composite construction has been used in the construction of the latest range of Crusader Caravans. The result is an outstanding range of superior quality caravans fast becoming the choice of those in the know.

Crusader Caravans chose composite panels by Creative Composites as they are among the highest-quality. But it’s not just the material that is exceptional. The unique production methods applied by the skilled team at Crusader Caravans are key to achieving a top quality caravan.

Often cited by industry experts as the future of caravan construction, it is expected many more caravan manufacturers will transition to full composite construction in the near future. You will hear a lot more about composite material and its benefits over the coming years.

WHY CHOOSE COMPOSITE?

WHAT IS ECOLITE™?

EcoLite™ is an advanced full composite construction method used by Crusader Caravans to form the external structure of the caravan. The walls/floor/roof are each made in one piece, so there’s no joins throughout the panels. This innovative method creates an outer shell that offers structural integrity, weather resistance and enhanced thermal properties. This means your caravan will be stronger, lighter and superior to traditional build caravans.

TRADITIONAL CARAVAN CONSTRUCTION

NEW ECO LITE CARAVAN CONSTRUCTION

Crusader’s EcoLite panels are timber-free

Crusader’s composite panels are less susceptible to rot, decay, and insect damage unlike timber constructed vans. This means that caravans constructed using EcoLite panels maintain their structural integrity over the long term. Additionally, composite panels are typically lighter than timber-framed walls. This results in a weight reduction in full composite caravans, leading to improved fuel efficiency, easier towing, and reduced stress on the towing vehicle.

Are there different

types of composite

material?

There are many different types of composite material.

Take a closer look.

Not all composite material is the same

There are different types of composite material. Crusader Caravans insist on the best quality.

The EcoLite composite material in use by Crusader Caravans comprises of three layers of high-quality materials. The two outer layers are made from high-quality fibreglass GRP (Glass Reinforced Polyester). The type of GRP used for the floor of Crusader Caravans is a super strong woven roving GRP; making it far stronger compared to other types of composite floors used by other caravan manufacturers.

The inner layer used by Crusader Caravans is made from structural XPS foam. XPS stands for eXtruded, high strength, closed-cell PolyStyrene. The XPS foam used in Crusader’s composite panels is 400 kPa rated, which has a higher structural strength than most XPS foam used by other manufacturers.

Simply put, this is one of the highest quality composite products available on the Australian market today. The result is a super high strength to weight ratio: making it the perfect material to build a caravan with. It’s no wonder very similar material is commonly used in aircraft cabins including the aircraft floor and ceiling panels.

- DID YOU KNOW?

What’s inside an EcoLite panel?

Just like inspecting a house, you need to know what’s inside the walls, roof, and floor of a caravan before you buy it. What’s inside can make a big difference to the life of your caravan. The team at Crusader are experts in building top quality caravans. Crusader’s unique EcoLite composite material and methods ensures the roof, floor and walls of a Crusader Caravan is far superior. Crusader acknowledge that each individual area of the caravan has a different job to do, so the nature and composition of the material chosen differs throughout. Crusader engineers have used three slightly different custom designed EcoLite composite panels in every caravan, each with differing properties. The following illustrative diagrams help explain the differences.

Roofing

A core requirement of the roof is to protect you against all Australian weather conditions. The EcoLite roof of a Crusader Caravan is hail resistant, water-resistant and contains superior thermal properties. This means you will stay warmer in winter and cooler in summer. The one-piece front wall and roof also have a stronger, higher tensile fibreglass skin which better handles the G-forces applied when breaking and accelerating. All walls and roof on Crusader Caravans are engineered to have a much higher impact strength to better withstand chipping, scratching and minor accidents.

WHY COMPOSITE?

Roofing

Crusader Caravans EcoLite roof is the thickest composite roof in Australia at 40mm (and 30mm in CRV models). Offering outstanding strength, durability, and insulation for your peace of mind.

- 50% Woven roving fibreglass (300gsm) and 50% Chopped strand mat fiberglass (300gsm)

- Structural 400kPa rated XPS foam (eXruded, high strength, closed-cell PolyStyrene)

- 50% Woven roving fiberglass (300gsm) and 50% Chopped strand mat fiberglass (300gsm)

Walls

Crusader Caravans EcoLite walls offer exceptional insulation and thermal properties, ensuring a comfortable journey in any weather condition.

- Chopped strand mat fibreglass (600gsm)

- Structural 400kPa rated XPS foam (eXtruded, high strength, closed-cell PolyStyrene)

- 50% Woven roving fibreglass (300gsm) and 50% Chopped strand mat fibreglass (300gsm)

Flooring

Crusader Caravans EcoLite floor, one of the thickest in the industry at 40mm (50mm in the XCountry), provides superior thermal insulation and a remarkably robust foundation for your caravan.

- Chopped strand mat fibreglass (440gsm) Woven roving fibreglass (300gsm)

- Structural 400kPa rated XPS foam (eXtruded, high strength, closed-cell PolyStyrene)

- Chopped strand mat fibreglass (440gsm) Woven roving fibreglass (300gsm)

XPS Foam

Woven roving fibreglass

Chopped strand mat fiberglass

Crusader Caravans EcoLite full composite builds are better. Here's why...

It pays to do your homework. Not all composite caravans are equal. Simply put, the quality of the EcoLite composite materials and the manufacturing processes used by Crusader are industry leading. Here’s the top 3 reasons why.

Crusader Caravans use world-leading EcoLite composite panels.

Crusader Caravans insist on the best for its customers at all times. The nature of the EcoLite composite material used by Crusader Caravans is exceptional. The material is sourced from Creative Composites, a Melbourne manufacturer who purchase the world’s best fibreglass and XPS foam from European suppliers.

Crusader Caravans have extensive experience working with composite materials.

Crusader Caravans have pioneered industry leading composite manufacturing techniques through extensive research and development. The team at Crusader Caravans know how to get the best out of this material, continuously striving for improvement. Some caravan manufacturers have only recently started experimenting with this new material. When it comes to working with new materials, experience counts.

HANDY HINT: if you are considering an alternative full composite caravan, remember experience counts, do your homework don’t just take a salesperson’s word. Crusader Caravans are industry leaders with 5 years experience working with composite panels.

Crusader Caravans has advanced manufacturing techniques - no frame needed.

As a multi award winning manufacturer, Crusader Caravans know how to make some of the best quality caravans available in Australia. Compare us with the rest.

Having worked with composite material for over 5 years, Crusader Caravans have refined their manufacturing practices to deliver a super strong caravan with all core caravan panels interlocked. Just like a plane each component is held solidly in place with just the right amount of flex needed to allow for natural movement of the caravan during transit.

EcoLite composite material enables a one-piece construction method for the roofs, floors and walls of a caravan. This means less joins so far less chance of water penetration. This also results in a more solid construction method.

The internal cabinetry and external walls are firmly locked into place via a secure interlocking method developed by Crusader Caravans. This precise tongue in groove method creates a solid assembly optimising structural integrity and weight distribution, while firmly anchoring furniture to the core of the caravan. The result is a strong and durable caravan that’s built to last.

The advanced methods in use by Crusader Caravans results in a high-quality caravan that’s super strong and able to fully support the caravan without the need for a frame. The absence of a frame means the caravan is as light as possible, and therefore much easier and more economical to tow. The absence of a timber frame in particular also means less chance of timber rot resulting from water ingress.

Attention to detail is applied at every step of the manufacturing process, including interlocking panels, J-mould end caps right down to the screws used to hold the panels securely while the adhesive cures. Crusader Caravans design and make their own screws and j-mould end caps because these products didn’t exist in the marketplace.

Polymer adhesive used by Crusader Caravans to bond furniture components to the caravan is super strong. In fact, the same adhesive is commonly used in bonding bus frames, vehicle windshields, truck cabins and body structures of trains. This is because this adhesive is strong, reliable, and environmentally friendly.

There are many more unique manufacturing techniques but they are confidential as they represent a significant competitive advantage to Crusader Caravans.

The end result is a super tough and light caravan that will give you years of enjoyment.

DID YOU KNOW? The advanced materials and manufacturing techniques employed by Crusader Caravans means they can build a fully composite caravan without the need for any metal frame or timber frame. The absence of a timber or metal frame means the caravan is much lighter and easier to tow, achieving much better fuel efficiency on the tow vehicle. No timber frame also means no chance of timber rot in the frame.

Why EcoLite Composite Panels?

Composite material is the future of caravan manufacturing and is expected to become the new industry norm. This is because it’s lighter, stronger, more water-resistant and better insulated. Crusader Caravans are proud to be at the forefront of this exciting innovation having pioneered EcoLite composite construction. This unique combination of advanced materials and manufacturing processes produces caravans of the finest quality. EcoLite by Crusader Caravans offers many benefits over the alternatives.

Superior strength

EcoLite composite material is lightweight yet super tough. The high strength to weight ratio of the material results in a high-quality caravan that’s better able to withstand the harsh Australian road and weather conditions.

Lighter weight

The combined weight of all the caravan panels makes a big difference to the overall weight of a caravan. The lightweight nature of EcoLite composite panels results in an overall lighter caravan that’s easier to tow. This means a broader range of vehicles will be able to tow the caravan. The lighter nature of the caravan also means you can carry more of your personal belongings inside without the risk of being overweight.

Managing your caravan weight is very challenging for any caravan owner, whether you are a first timer or a pro. The combined weight of your car and caravan (Gross Combined Mass) must be within the vehicle’s legal limits (consult your vehicle manual).

HANDY HINT: if you are considering an alternative full composite caravan, don’t forget to ask where the composite material is made. Some imported composites are made using inferior materials. The EcoLite composite material in use by Crusader Caravans is made in Australia using European premium components and advanced manufacturing methods.

Water resistant

EcoLite composite material enables a one-piece construction method for our roofs, floors and walls. This greatly reduces the chances of any water seeping into your caravan. The one-piece construction method also results in a more durable caravan, better suited to the harsh Australian climate.

Superior thermal properties

EcoLite composite material offers better insulation so you can stay cooler in summer and warmer in winter. This means your desired internal temperature can be achieved quicker using less energy. This is a great advantage particularly during off-grid situations.

Fuel efficient

As a caravan made from EcoLite composite material is lighter, the tow vehicle will use less fuel saving money and the environment.

Noise insulation

EcoLite composite panels deliver far superior noise insulation creating a peaceful and tranquil atmosphere inside the caravan. Any noise coming from inside or outside your caravan is much less likely to travel beyond your caravan walls. The premium acoustic properties of the EcoLite composite panels will make a big difference when staying in caravan parks or crowded places during the holiday season. You will quickly appreciate the sound-proof properties that this product has.

Hail resistant

The tough nature of the external fibreglass skin provides far superior protection from hail stones compared to traditional aluminium. This is why many insurance providers offer a discount on insurance premiums.

HANDY HINT: Some insurance providers offer a discount on insurance premiums for caravans built with composite material. Please check with your insurance provider.

Modern and sleek

EcoLite composite panels result in a smooth, more modern finish that looks great. There’s also far less joins which means less dust and grime. Your Crusader Caravan will look sharp after any big adventure; even if you’ve just returned from the outback.

Strong resale value

Full composite caravans are highly sought after amongst caravan buyers, especially caravans made by Crusader Caravans using EcoLite composite construction. The market is becoming increasingly aware of the advantages of this form of construction. With no timber frame, potential purchases of used caravans are more confident to purchase full composite.

FREQUENTLY ASKED QUESTIONS

How can I tell the difference between one full composite caravan and another? What should I be looking for?

It pays to do your homework. Not all full composite caravans on offer are equal. There are differences in the quality of the composite material. There are also differences in the manufacturing methods employed.

Ask where the composite material is made

Some composite materials made overseas offer inferior quality. The quality of the EcoLite composite material used by Crusader Caravans is exceptional, it is Australian-made using European premium components. Simply put, this is one of the highest quality composite products available today which is perfectly suited for caravan panels. The result is a super high strength to weight ratio: making it the perfect material to build a caravan with. It’s no wonder very similar material is commonly used in aircraft cabins including the aircraft floor and ceiling panels.

Ask about the nature of the foam inside a composite panel

Crusader Caravans use only the highest quality XPS foam inside their composite panels. Crusader use a 400 kPa Structural XPS closed cell foam that provides structural strength as well as being a closed cell foam that will not soak up water. Some other caravan manufacturers use an open cell foam which can retain water. XPS foam also has superior thermal properties over open cell foams making a far better insulator.

Ask how much experience the manufacturer has working with composite material

Whilst some caravan manufacturers have only just started to experiment with composite material, Crusader Caravans first started working with composite material 5 years ago. The manufacturing methods employed by Crusader are advanced and validated by our Research and Development team. t’s Crusader Caravans’ acute attention to detail that makes the difference. For instance, Crusader Caravans worked closely alongside representatives from the polymer adhesive manufacturer to fine tune methods on the Crusader Caravans production line. The result is the best possible and strongest application of the polymer adhesive product.

Another great example of the Crusader difference is the extensive work Crusader engineers have done to ensure EcoLite composite panels are optimised. Crusader engineers have used three slightly different composite panels, each with slightly different tolerances to achieve one of the most robust caravans in Australia:

The floor is thicker than the walls and roof giving better insulation from the cold ground at night, whilst also forming a super rigid base to build the caravan on.

The one-piece front wall and roof have stronger, higher tensile fibreglass skin which better handles the G-forces applied when breaking and accelerating.

The remaining walls are engineered to withstand downward force to support the roof and are strong enough to ensure structural integrity.

Ask if the manufacturer offers a 100% full composite structure or only partial

Some caravan manufacturers use a combination of composite panels as well as other types of material for their caravan production. The best builds consist of 100% composite panels, formed by 2 outer fibreglass layers and an XPS inner core, for all the walls, floor and roof, with no timber frame.

How is the furniture inside a Crusader Caravan locked into place?

All furniture (cabinets, seating, bedding etc) inside a Crusader Caravan is built from plywood (no chip board) and is firmly attached to the floor before the walls and roof are installed. Done this way, the cabinetry is free-standing and self-supporting. Crusader Caravans then use polymer adhesive to attach the furniture to the walls. The result is a super rigid structure.

This type of adhesive is commonly used in bonding bus frames, vehicle windshields, truck cabins and body structures of trains.

Designed with interlocking panels and screwed together, the furniture is not only very robust but it maintains its structure even when towed on rough corrugated roads.

This precise tongue in groove method creates a solid assembly optimising structural integrity and weight distribution, while firmly anchoring furniture to the core of the caravan. The result is a strong and durable caravan that’s built to last.

Does a full composite caravan require a frame inside the wall panels?

A well-built full composite caravan does not require a frame inside the wall panels.

A high-quality composite material (such as the one in use by Crusader Caravans) is super strong and able to fully support the caravan without the need for a frame. The absence of a frame means the caravan is as light as possible, and therefore much easier and more economical to tow. The absence of a timber frame in particular also means less chance of timber rot resulting from water ingress.

Australian

made

5-year structural warranty

MULTI-AWARD WINNING MANUFACTURER

2-year national warranty

quality

assured